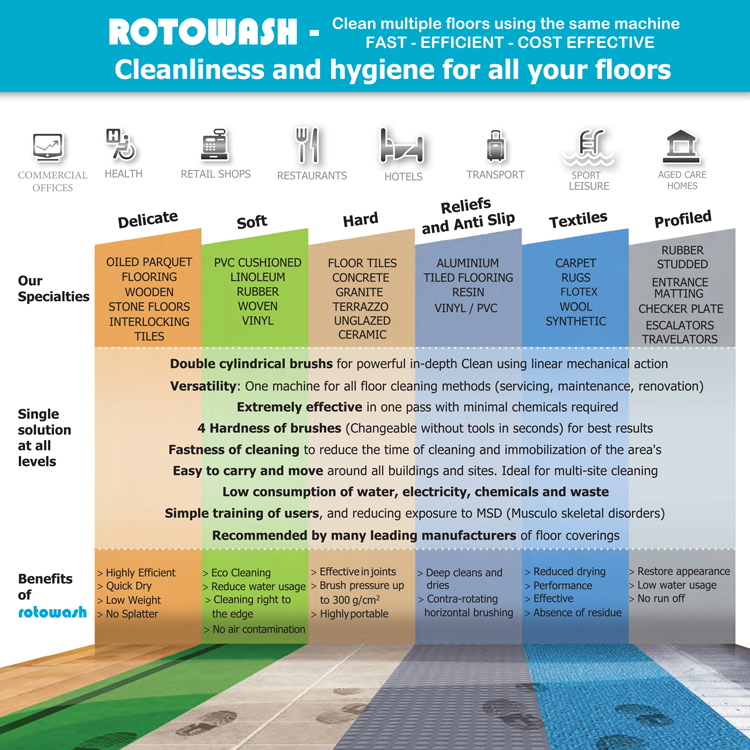

Quality Accessories For Quality Machines

Rotowash machines and accessories are built to the highest international standards on quality, design, electrical and safety, without exception and without compromise.

Brush guidance, brush wear and how to properly care and maintain your brushes.

Rotowash machines and accessories are built to the highest international standards on quality, design, electrical and safety, without exception and without compromise.

Rotowash Brushes

Rotowash BrushesHigh quality and long lasting, Rotowash cylindrical brushes are designed to enhance and extend the cleaning method of the entire Rotowash range of floor cleaning machines. Color coded to prevent cross-contamination.

STANDARD black bristle brushes come with a choice of colour coded cores and end caps to help raise cleaning safety standards.

STANDARD black bristle brushes come with a choice of colour coded cores and end caps to help raise cleaning safety standards.

Available in black, blue, red, yellow and green to give you total freedom of

choice in your cleaning safety policy.

Rotowash brushes are specifically designed to enhance and extend the cleaning method of the Rotowash range of professional floor cleaning machines.

Rotowash brushes are constructed from high quality polypropylene materials and meet the highest British and E.E.C standards on quality, safety and design.

Rotowash brushes work effectively with most modern cleaning chemicals.

| Floor Type | Guide in Hours |

|---|---|

| Carpet – 0 to 2mm pile | 700-1000 |

| Carpet – 2 to 7mm pile | 1000-1200 |

| Ceramic (smooth) | 280-320 |

| Ceramic Tiles (slip resistant) | 220-240 |

| Checkerplate | 140-180 |

| Concrete | 180-220 |

| Entrance Matting (aluminum slips/carpet with metal fibers) | 120-150 |

| Flotex soft flooring | 700-1000 |

| Laminate – Wood | 650-750 |

| Linoleum | 650-750 |

| Polyurethane coated rubber sports floors (ie Rebound Ace) | 550-650 |

| Quarry Slate Terracotta Tiles | 280-320 |

| Resin | 180-220 |

| Rubber (studded/ribbed) | 550-650 |

| Vinyl (slip-resistant) | 180-220 |

| Vinyl (smooth) | 650-750 |

| Wood | 650-750 |

| Escalator Treads (aluminum) | 100-120 |

Based on the correct brush care maintenance, average quality of floor and normal floor soilage.